Phone:(800) 323-2440

E-mail:kamflex@kamflex.com

High-quality processing equipment

Kamflex is proud to introduce our line of specialty conveyors and other products for industries throughout the world. Our company knows that the industries we serve require highly reliable, sanitary processing equipment and we have the tools to make that happen.

We’ve developed outstanding quality items that make automation much easier for your company. Please browse our selection below and let us know if we can answer any questions about the type of equipment that would work best for your particular application.

These vertical belt conveyors are appropriate for many applications where multiple product drop points are not required. In many instances, vertical belt conveyors provide significant sanitation,

cost, maintenance, and/or floor space advantages over bucket elevators.

Preferred belt for these conveyors is a plastic belt with scooped cleats.

Features and Benefits:

More Sanitary-

- Quick-belt tension release (with fabric belt)

- Standoffs on legs with angled end-caps

- Tool-free removable front panels

- 304 or 316 stainless frames, polished to a No. 4 finish

- Continuous TIG welds-ground & polished

Better Functionality-

- Stainless steel bearing housings with no-re-lube inserts

- Vacuum breakers (with fabric belt)

- 2-inch square tubing supports

- 12-gauge formed frames

- Stainless steel pulleys (standard)

Series 811 Cleated Plastic Belt Z Conveyor

These inclined plastic belt conveyors are engineered for a wide range of product elevating applications including rinsing, cooling or drying. Production requirements through any angle of incline can be met by varying the effective belt width and cleat height/spacing combinations. The belt is positively driven (with sprockets), providing improved tracking and torque transmission. Belting material choices include FDA approved polypropylene, polyethylene and polyacetal, each with the ability to meet USDA Meat & Poultry and USDA-Dairy restrictions. Other options to meet you specific needs include infeed hoppers, discharge transfer chutes, casters and variable speed drives to name a few.

ADDITIONAL QUALITY FEATURES & BENEFITS:

More Sanitary:

- Standoffs on legs with angled end caps

- 304SS frame polished to a No. 4 finish

- Continuous TIG welds, ground & polished

- Washdown duty frame is standard (washdown motor is an option)

Better Functionality:

- Tool-free removable side rails 1” higher than cleat height

- 303SS bearing housings

- 2” square tubing supports

- 12-gauge formed frames

- 10-gauge formed motor platforms

- 1½” square, 303SS solid drive & idler shafts

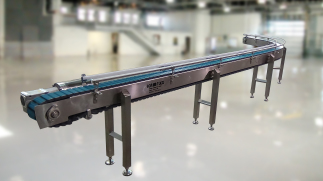

Series 704 Flat Fabric Belt Conveyors

These fabric belt conveyors are engineered for a wide range of product handling applications. Frames can be flat or troughed. Belting choices feature FDA approved materials, including sealed belt edges for USDA Meat & Poultry applications. Other options to meet you specific needs include variable speed drives, casters and side rails to name a few.

ADDITIONAL QUALITY FEATURES & BENEFITS:

More Sanitary:

- Tool-free Quick-belt tension release mechanism

- Optional tool-free removable side rails

- Standoffs on legs with angled end caps

- 304SS frame polished to a No. 4 finish

- Continuous TIG welds, ground & polished

- Washdown duty frame is standard (washdown motor is an option)

Better Functionality:

- 303SS bearing housings

- Vacuum breakers on slider bed

- 2” square tubing supports

- 12-gauge formed frames

- 10-gauge formed motor platforms

- 304SS pulleys (standard)

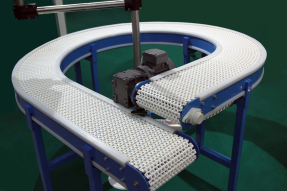

Series 899 Table Top Chain

These plastic table top chain conveyors are engineered for a wide range of packaged product handling applications. The belt is positively driven (with sprockets), providing improved tracking and torque transmission. Belting material choices include FDA approved, low friction polyacetal. This material, for example, has low back-pressure properties; perfect for product accumulation. Other options to meet you specific needs include variable speed drives, casters and radial turns to name a few.

ADDITIONAL QUALITY FEATURES & BENEFITS

More Sanitary:

- Standoffs on legs with angled end caps

- 304SS frame polished to a No. 4 finish

- Continuous TIG welds, ground & polished

- Washdown duty frame is standard (washdown motor is an option)

Better Functionality:

- Optional fully adjustable product guide rails

- 303SS bearing housings

- 2” square tubing supports

- 12-gauge formed frames

- 10-gauge formed motor platforms

- 1” diameter, 303SS solid drive & idler shafts

Series 705 Cleated Fabric Belt Conveyor

These inclined fabric belt conveyors are engineered for a wide range of product elevating applications. Production requirements through any angle of incline can be met by varying the belt width and cleat height/spacing combinations. Belting choices feature FDA approved materials, including sealed belt edges for USDA Meat & Poultry applications. Other options to meet you specific needs include infeed hoppers, discharge transfer chutes, casters and variable speed drives to name a few.

ADDITIONAL QUALITY FEATURES & BENEFITS:

More Sanitary:

- Tool-free Quick-belt tension release mechanism

- Standoffs on legs with angled end caps

- 304SS frame polished to a No. 4 finish

- Continuous TIG welds, ground & polished

- Washdown duty frame is standard (washdown motor is an option)

Better Functionality:

- Standard tool-free removable side rails, 1” higher than cleat height

- 303SS bearing housings

- Vacuum breakers on slider bed

- 2” square tubing supports

- 12-gauge formed frames

- 10-gauge formed motor platforms

- 304SS pulleys (standard)

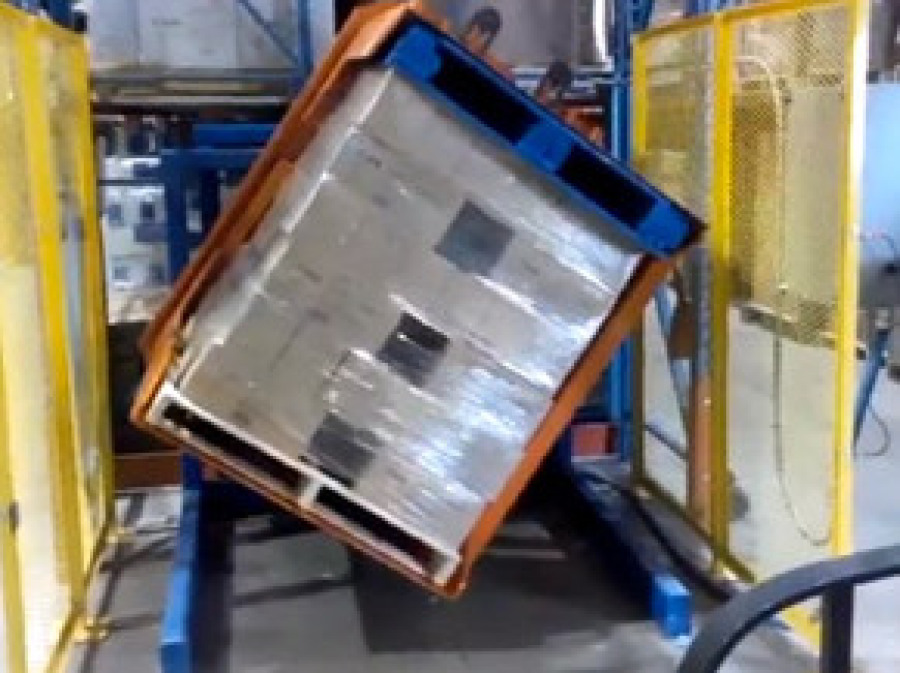

Series 901 Rotary Turn Table

These units are used for product accumulation, manual packaging and case filling applications. Typically, product is transferred from a packaging or bagging machine to this turn table via a

cleated belt conveyor; operators will then pick and place the product into cases. The circular top is a one piece, 12-gauge 304SS disc formed by a metal spinning process. Integral

flanges or a dished contour results in a more sanitary design.

Series 901 Turn-Tables are available in three versions, depending on the drive mechanism:

- 901 A: 1.8 RPM, Friction wheel drive, constant speed (For light product loads)

- 901 B: 6 RPM, Direct drive, constant speed (For heavier, uneven product loads)

- 901 C: 1.5 - 6 RPM, Direct drive, variable speed (For heavier, uneven product loads)

In a somewhat related design variation, 1” thick UHMW tops are available for accumulation or the unscrambling of glass or plastic bottles.

ADDITIONAL QUALITY FEATURES & BENEFITS:

- All 304SS construction

- 12-gauge, 304SS formed top, sand blast finish

- 2” square tubing frame polished to a No. 4 finish

- Continuous TIG welds, ground & polished

- Washdown duty frame is standard (washdown motor is an option)

- Includes motor starter and/or SCR variable speed controller

Series 310 Roller Conveyors

Typical applications utilizing roller conveyors include processing meat and dairy products or transferring trays or packaged products. The sanitary roller and frame designs easily meet USDA Meat & Poultry or USDA-Dairy requirements. Rollers can be plastic or stainless steel, depending on the application.

Gravity roller sections are most common. However, powered roller sections are realized through rollers with double sprockets, daisy chained together or line-shaft drive configurations.

ADDITIONAL QUALITY FEATURES & BENEFITS:

More Sanitary:

- 304SS frame polished to a No. 4 finish

- Continuous TIG welds, ground & polished

- Washdown duty frame is standard (washdown motor is an option)

Better Functionality:

- 14-gauge, formed chain guard

- 303SS bearing housings

- 2” square tubing with optional supports

- 12-gauge formed frames

- 10-gauge formed motor platforms